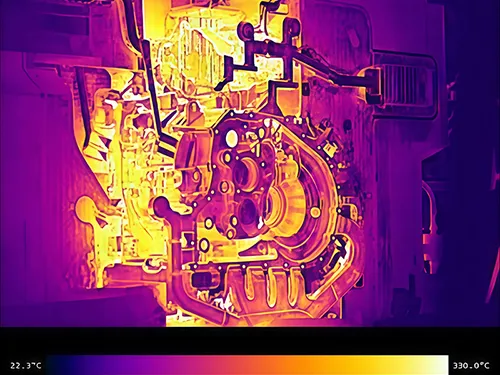

The mold infrared sensing system (miss) uses infrared thermal imaging cameras to monitor and record mold temperatures at key points in real time during the die casting cycle. It analyzes and processes temperature data to detect whether the die casting process is operating normally, enabling production traceability. In the die casting field, precise control of mold temperature plays a decisive role in product quality, production efficiency, and mold service life.

| Model |

|

|

| Number of infrared cameras | 2 | 4/6/8 |

| Display | 27-inch monitor ×1pc | 27-inch monitor ×2pcs |

| Applicable die-casting machine | Die casting machine with capacities 2500T or less | Die casting machine with capacities above 2500T |

| Infrared camera brand | InfiRay/Guide Sensmart | InfiRay/Guide Sensmart |

| Infrared camera resolution | 300,000 pixels | 300,000 pixels |

| Temperature measurement range | -20°C ~ 550°C | -20°C ~ 550°C |

| Temperature measurement accuracy | ±2% | ±2% |

| Temperature measurement trigger mode | External trigger or IO signal | External trigger or IO signal |

| Protection level of infrared camera | IP65 | IP65 |

| Cooling method of infrared camera | Forced air cooling | Forced air cooling |

| External power supply | 220V-50Hz | 220V-50Hz |

Temperature measurement is triggered automatically based on signals from external equipment (such as die casting machines).

Free configuration of measurement zones, supporting multiple shapes and unlimited quantity.

Standard temperatures and alarm limits can be set for each zone.

Ensures stable and accurate temperature measurement.

Operating data fully recorded, with storage for at least six months.

Exportable tables and curves.

Can be upgraded to integrate with temperature control systems for automatic stabilization of mold temperature.

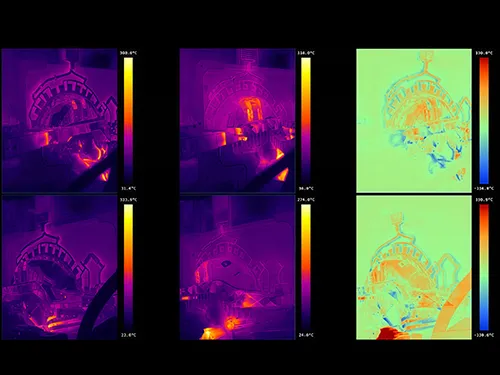

Displays real-time images and temperatures from all cameras.

Displays images before spraying, after spraying, and the differences between them.

We provide complete mold temperature control solutions to help you achieve stable quality, shorter cycles and reduced costs. Let’s find the right system for your needs.

Temperature fluctuations can be caused by several factors. These include faulty or improperly calibrated temperature sensors, issues in the heating or cooling systems (such as damaged heating tubes or clogged cooling pipelines), or poor mold heat dissipation. Unreasonable process parameter settings may also contribute. Regular inspection, cleaning, and parameter optimization can help stabilize the system.

First, check the power supply to ensure connections are intact and switches, plugs, or circuits are not damaged. If power is normal, check whether the overload protection device has been triggered. If neither is the case, the issue may lie in the control system or a key component. In that case, contact professional after-sales personnel for further diagnosis.

Standard warranty is 12 months from acceptance. It covers non-human faults with free repairs, replacement of faulty parts, and technical support.

A response system is in place with performance tracking. If service is unsatisfactory, customers may escalate complaints to customer support, which ensures follow-up by assigned personnel.