Contour spraying for die casting molds uses robotic equipment to precisely and uniformly apply release agents and other media to designated areas of the mold surface, based on the three-dimensional shape, structural features, and preset paths of the mold cavity. Through “contour spraying,” the release agent only covers critical working surfaces such as mold cavities and runners, avoiding unnecessary spraying that causes waste or affects casting quality. It ensures uniform coating thickness to meet demolding requirements while preventing defects caused by excessive coating (such as bubbles and shrinkage porosity) or mold sticking caused by insufficient coating.

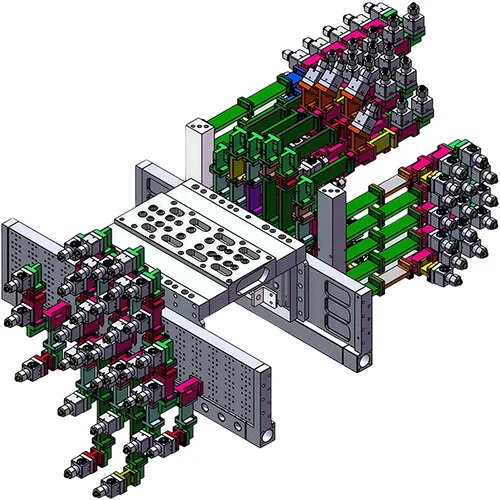

The clutch housing contour spraying fixture adopts a modular structure, designed according to cavity characteristics. It builds the spraying fixture and is equipped with an additional air-blowing function, enabling independent control of multiple spraying circuits and rapid drying of the mold cavity.

Multiple modular contour assembly methods ensure smooth delivery of liquid and air channels, allowing the spraying fixture to be adapted precisely to the mold.

With modular contour assemblies, spraying angles and distances can be flexibly adjusted.

The modular contour structure helps reduce maintenance costs during later use. Only damaged connectors need to be replaced for continued use.

Professional 3D design of contour spraying fixtures enables spraying cycles of 25–30 seconds. With adjustments to the mold’s internal cooling structure, spraying cycles of under 20 seconds can be achieved.

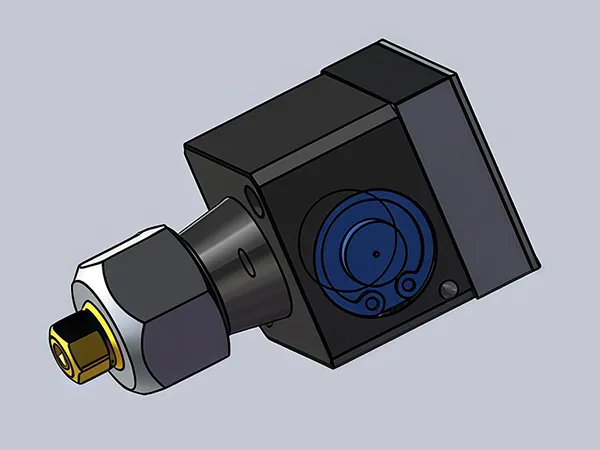

| Applicable release agents/die lubricants | Water-based, oil-based |

| Air pressure | 4-6bar |

| Release agent transfer pressure | 6-12bar |

| Spray method | Common spray |

| Spray circuits | 4+4 |

| Die spraying tool weight | Depending on actual application |

| Die spraying tool length | Depending on actual application |

We provide complete mold temperature control solutions to help you achieve stable quality, shorter cycles and reduced costs. Let’s find the right system for your needs.

Standard warranty is 12 months from acceptance. It covers non-human faults with free repairs, replacement of faulty parts, and technical support.

A response system is in place with performance tracking. If service is unsatisfactory, customers may escalate complaints to customer support, which ensures follow-up by assigned personnel.