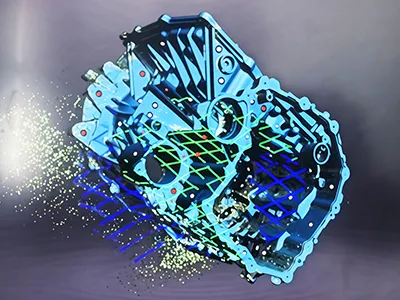

Our company focuses on research in die casting mold temperature control. The mold workshop covers an area of 6,600㎡, and the total plant area is 25,000㎡. By integrating mold design with temperature control systems, the company is committed to improving product qualification rates in the automotive die casting industry, reducing cycle times, lowering production energy consumption, extending mold service life, and increasing mold utilization.

500T Clamping Machine

500T Clamping Machine 500T Clamping Machine

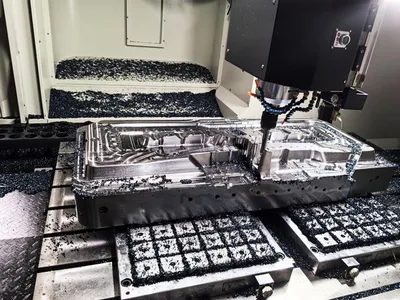

500T Clamping Machine| Manufacturer | Model | Quantity |

| Tianrui | VF1615 / VF2318 | 3 units |

| Tianrui | VL1100A | 3 units |

| Haitian | Overhead Gantry 5-Sided Machining Center BM4060 | 1 unit |

| Haitian | GLUe16II PLUS / GLUe13II PLUS | 2 units |

| Makino (Japan) | V80S / V90S | 2 units |

| Manufacturer | Model | Equipment Type | Quantity |

| HSPK Hanba | HF180 / HF130A / HF100 | EDM (Spark Erosion) | 3 units |

| OMILON | — | Dual-Head EDM | 2 units |

| HQ Hanchi | HQ800GS1 / HQ1200F3 / HQ1600F3 | Wire Cutting | 3 units |

| Accurate | DH-1616B | 3-Axis Deep Hole Drill | 2 units |

| Accurate | DH-1816B | 5-Axis Deep Hole Drill | 1 unit |

EDM (Electrical Discharge Machine)

EDM (Electrical Discharge Machine) EDM (Electrical Discharge Machine)

EDM (Electrical Discharge Machine) Wire Cutting

Wire Cutting Wire Cutting

Wire Cutting Deep Hole Drill

Deep Hole Drill

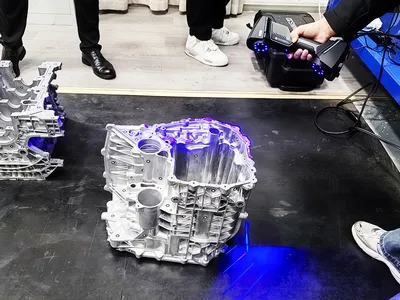

| Equipment Name | Model | Quantity |

| SIMSCAN 3D Scanner | SIMSCAN30 | 1 unit |

| Coordinate Measuring Machine (CMM) | 2100×1600×800 | 1 unit |

| Mold Processing Time (T1) | Machine Tonnage Range |

| 32 days* | ﹤500T |

| 38 days* | ﹤800T |

| 42 days* | ﹤1600T |

| 45–60 days* | ﹤3200T |

| 55–70 days* | ﹤5000T |

| 90–100 days* | ﹤8800T |