As an internationally recognized provider of integrated mold temperature control solutions, Xinyu has successfully applied its self-developed centralized mold temperature control system (CTCU) across industries such as die casting structural parts, automotive components, electronic housings, and aerospace parts. These applications have solved the challenges of low efficiency, high energy consumption, and difficult maintenance common in traditional decentralized temperature control systems, ensuring stable product quality.

13,000T using Xinyu mold temperature machines and the CTCU centralized mold temperature control system.

9000T using Xinyu centralized CTM water mold temperature machine and CTCU centralized mold temperature control system

8800T using Xinyu centralized CTM water mold temperature machine, CTCU centralized mold temperature control system, thermal imaging system, and piping system. Currently more than 60 units installed.

8800T using Xinyu centralized CTM water mold temperature machine and CTCU centralized mold temperature control system.

7200T using Xinyu centralized CTM water mold temperature machine, mold-side cooling unit, and CTCU centralized mold temperature control system. Currently more than 80 units installed.

First in China to use Xinyu high-temperature water mold temperature machine, mold-side cooling unit, and CTCU centralized mold temperature control system.

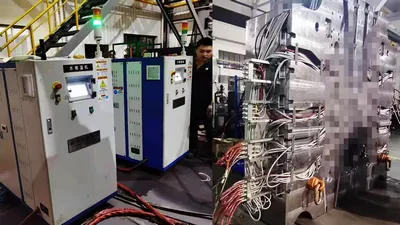

Using Xinyu CTCU centralized mold temperature control system with 20 water mold temperature machines and 10 oil mold temperature machines.

Equipped with Xinyu full series of oil mold temperature controllers.

Equipped with Xinyu CTM integrated water mold temperature controller, mold cooling unit, and oil mold temperature controller.

IKD now uses more than 300 units of Xinyu temperature control equipment.

Currently using 15 sets of Xinyu temperature control units and more than 30 pieces of equipment, including high-pressure spot cooling machines, mold temperature controllers, and pure water systems.

Strategic cooperation with Xinyu, with over 300 temperature control units in operation.

All temperature control equipment supplied by Xinyu, with a five-year strategic agreement signed. More than 100 units currently in operation.

LK 4500T – Temperature control unit, currently more than 80 units in operation

Equipped with temperature control unit, currently more than 40 units in operation

Temperature control unit, currently more than 60 units in operation

Large molds above 6000T are equipped with Xinyu temperature control systems

On-site customer test data: total machine power 30KW, actual average power consumption 5.7KW/H