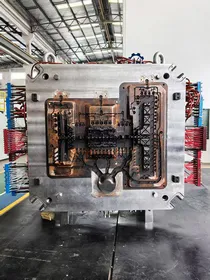

The precision of the mold is the first safeguard of die casting quality. We rely on advanced technologies such as 3D scanning and finite element analysis to build a fully digital design system from product drawings to mold forming. Through reverse engineering, we accurately restore product details, and with mold flow analysis (MFA) software, we simulate the flow of molten metal in the cavity to prevent defects such as shrinkage porosity and flash in advance.

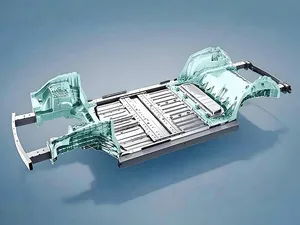

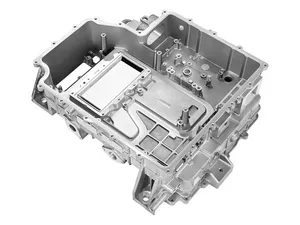

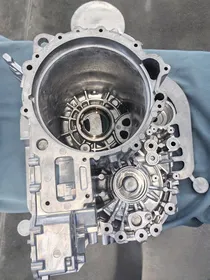

Our workshop is equipped with five-axis machining centers and high-precision EDM machines, achieving machining accuracy within ±0.005 mm. This ensures that the difference between mold cavity and product design is nearly zero. Whether it is a complex automotive transmission housing mold or a thin-walled new energy battery case mold, we can achieve the high standard of “qualified in the first trial,” helping customers shorten product launch cycles.

Before customer acceptance, we introduce professional temperature control equipment for hot mold debugging, adding an extra layer of “insurance” for precise operation and long service life of molds. During operation, the uniformity and stability of mold temperature directly affect the dimensional accuracy of die castings. By using temperature control equipment, we can precisely control the temperature of each area of the mold, achieving thermal balance under simulated production conditions.

In this process, we can promptly detect dimensional deviations caused by uneven temperature distribution and make targeted adjustments, ensuring that delivered molds produce castings with minimal dimensional errors to meet strict customer requirements. At the same time, proper hot mold debugging avoids thermal stress caused by sudden temperature changes, reducing risks of mold cracking or deformation, and effectively extending mold service life by more than 20%. This allows customers to achieve higher cost-effectiveness in long-term production.

Mold delivery is not the end of cooperation but the beginning of mass production. We provide “all-round” after-sales service: during mold installation, our technical team offers on-site guidance to ensure perfect compatibility with die casting equipment. During mass production, we provide remote diagnostics or on-site support for issues such as increased burrs or dimensional fluctuations.

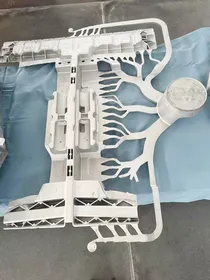

Chery New Energy Vehicle – Front Compartment Core Development for Little Ant Model

5000T Rear Longitudinal Beam Mold – Cycle Time Reduced from 120s to 80s

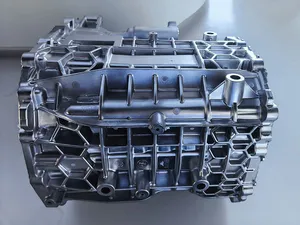

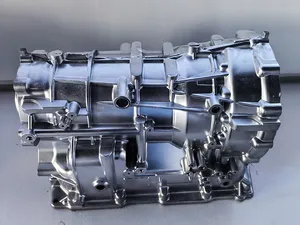

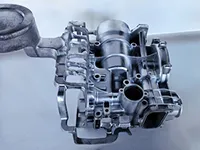

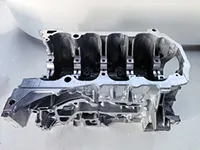

3000T SAIC GS62 Four-Cylinder Engine Block Mold – Cycle Time Reduced from 135s to 105s, Pass Rate Increased from 94% to 97%

5000T Backbone Mold – Cycle Time Reduced from 120s to 80s

2000T Tobia A-Pilla Mold – Cycle Time Reduced from 85s to 65s

3000T Three-in-One Housing Mold – Cycle Time Reduced from 160s to 95s

We provide complete mold temperature control solutions to help you achieve stable quality, shorter cycles and reduced costs. Let’s find the right system for your needs.

Check the temperature sensor, then verify heating and cooling systems, and review control settings. Compare normal operation data with current readings to locate anomalies.

Optimize channel design, position heating/cooling pipes strategically, and use effective heat-transfer media. For large molds, apply zoned temperature control for independent regulation.

Standard warranty is 12 months from acceptance. It covers non-human faults with free repairs, replacement of faulty parts, and technical support.

A response system is in place with performance tracking. If service is unsatisfactory, customers may escalate complaints to customer support, which ensures follow-up by assigned personnel.