Large integrated body die casting in the automotive parts industry.

| Model |

|

|

| Circulating circuits | 10 | 20 |

| Circulating pump power | 4kW | 5.5kW |

| Max. power consumption | 84kW | 84kW |

| Temperature adjustment range | 50-150°C | 50-150°C |

| Power supply | 3N-380V-50Hz | 3N-380V-50Hz |

| Heat transfer medium | Water | Water |

| Cooling method | Indirect cooling | Indirect cooling |

| Safety & alarm function | Pump reversal/Phase lack/Water shortage/Overtime/Overload /Undervoltage | |

| Cooling water piping | 1 inch | 1 inch |

| Circulating water piping | 1 inch | 1 inch |

| Machine dimensions | 1200×650×1300mm | 1200×650×1300mm |

A single CTM can replace more than ten traditional water temperature machines. For example, in a Haitian Metal 8800T ultra-large die casting island, the traditional solution required 30 water temperature machines, while the CTM solution only needs 3 units. Floor space is reduced from 30㎡ to 10㎡, with the ability to integrate more than 100 temperature control circuits and three temperature zones.

Equipment cost savings of more than 30%, installed power savings of more than 70%. For example, in the Haitian Metal 8800T ultra-large die casting island, total energy consumption was reduced from 1680KW in the traditional solution to 360KW.

Adopting a split structure design, the control box can be placed directly next to the mold to achieve intermittent water supply with fast response. At the same time, CTM divides temperature into three zones: low temperature zone 5–35℃, medium temperature zone 50–120℃, and high temperature zone 120–160℃. Through mold temperature data collection and centralized control, precise temperature control is achieved.

Delivery pressure above 1MPa, much higher than ordinary water temperature machines at 0.3–0.5MPa. Transmission efficiency is higher, heat transfer rate is nearly doubled, heating speed is faster, and heating/cooling efficiency is twice that of ordinary water temperature machines.

Can be linked with the MISS Mold Infrared Sensing System and the TCUI Central Mold Temperature Control System. Through a self-developed closed-loop control algorithm, it automatically stabilizes mold temperature and realizes fully automatic closed-loop control, leading the development of intelligent mold thermal balance.

Equipped with complete safety protection measures, such as water shortage alarms and pressure relief loop devices, to protect pumps and heating tubes. Process fault display functions make troubleshooting convenient without requiring professional maintenance personnel.

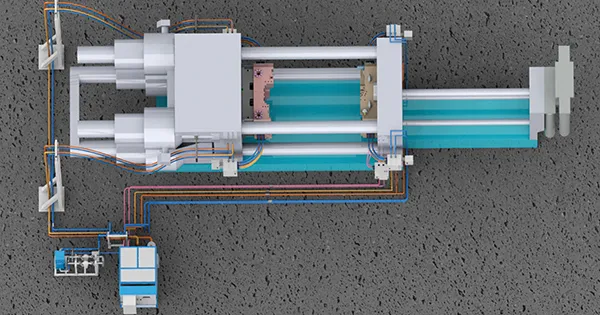

The CTM central mold temperature controller is a large high-temperature water circuit centralized control station. It replaces dozens of individual water temperature machines with centralized temperature control, dividing temperature into three major zones: low temperature zone 5–35℃, medium temperature zone 60–120℃ (or 50–120℃), and high temperature zone 150–180℃ (or 120–160℃). The control system is integrated into one large central water temperature control system.

The CTM adopts a split structure design, with the control box placed directly next to the mold. It can realize intermittent water supply with fast response, while centralized management reduces the number of pipelines, making insulation easier and minimizing heat loss. The delivery pressure is above 1MPa, with higher transmission efficiency and nearly double the heat transfer rate compared with ordinary water temperature machines. Heating and cooling efficiency is also twice that of ordinary machines. In addition, the CTM can be linked with the MISS Mold Infrared Sensing System and the TCUI Central Mold Temperature Control System to achieve fully automatic closed-loop control and stable mold temperature.

We provide complete mold temperature control solutions to help you achieve stable quality, shorter cycles and reduced costs. Let’s find the right system for your needs.

The suitable solution depends on the material (e.g., aluminum or zinc alloys), the complexity and size of the product, as well as production volume and efficiency targets. Compatibility with existing production equipment should also be considered. Technical staff can carry out a full evaluation and provide a customized solution.

Yes, in most cases it is possible, but a site survey is required. The assessment checks space layout, supporting utilities (power, water, oil), and compatibility with the existing control system. Based on these factors, a practical installation plan can be developed.

Standard warranty is 12 months from acceptance. It covers non-human faults with free repairs, replacement of faulty parts, and technical support.

A response system is in place with performance tracking. If service is unsatisfactory, customers may escalate complaints to customer support, which ensures follow-up by assigned personnel.