| Model |

|

|

|

|

| Cooling water circuits | Customizable: common mold cooling 12-36 circuits, high pressure spot cooling 12-120 circuits | |||

| Cooling water discharge pressure | Mold cooling 0.4-0.8MPa Spot cooling 0.6-1.2MPa |

Mold cooling 0.4-0.8MPa Spot cooling 0.6-1.2MPa |

Mold cooling 0.4-0.8MPa Spot cooling 0.6-1.2MPa |

Mold cooling 0.4-0.8MPa Spot cooling 0.6-1.2MPa |

| Max. working pressure | 13kW | 20kW | 29kW | 35kW |

| Water tank capacity | 500L | 600L | 1000L | 1200L |

| Water source | Clean tap water/pure water | Clean tap water/pure water | Clean tap water/pure water | Clean tap water/pure water |

| Water pressure of water source | 0.2-0.3MPa | 0.2-0.3MPa | 0.2-0.3MPa | 0.2-0.3MPa |

| Power supply | 3N-380V-50Hz | 3N-380V-50Hz | 3N-380V-50Hz | 3N-380V-50Hz |

| Machine dimensions | 1500×1100×1650mm | 1500×1350×1650mm | 1600×1300×1700mm | 1650×1400×1700mm |

| Spot cooling distributor dimensions | 560×190×390mm | 560×190×390mm | 560×190×390mm | 560×190×390mm |

| Mold cooling distributor dimensions | 560×190×370mm | 560×190×370mm | 560×190×370mm | 560×190×370mm |

The equipment provides two different pressure outputs: spot cooling 0.6–1.2MPa; mold cooling 0.4–0.8MPa.

The equipment uses Xinyu’s self-developed PID control module, which controls the high-pressure pump through a frequency converter to achieve rapid pressurization. Once the set pressure is reached, it maintains constant pressure regardless of the number of pipelines opened, ensuring stable operation.

The PID control module can automatically detect system pressure, so when cooling water is shut off, the pump stops running, maximizing energy savings.

Each group of pipelines can be controlled independently. Delay time and water supply duration can be set for each pipeline, enabling intermittent water supply.

After all spot cooling pipelines have completed water supply, the system can be set to blow air, drying residual water in the pipelines to prevent scaling.

Each pipeline is equipped with a flow monitoring system, allowing real-time display of water flow in the HMI. Alarm ranges can be set, and when flow is below the lower limit or above the upper limit, the unit triggers an alarm and can output alarm signals to the die casting machine.

Water supply records, flow curves, and mold process recipe information can be saved in the equipment.

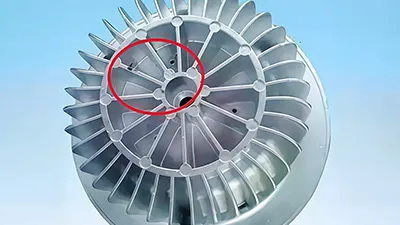

The die casting mold cooling unit from Xinyu Intelligent Technology is a dual-pressure output device that integrates spot cooling and standard cooling functions. The dual pressure output and spot cooling functions precisely address local high-temperature areas of die casting molds (such as gates and cores). By rapidly cooling these areas, it reduces defects such as product scuffing and mold sticking.

For example, in automotive engine cylinder head die casting, this equipment can quantitatively manage the flow and pressure of each cooling circuit to ensure mold thermal balance and avoid casting deformation caused by uneven temperature. In addition, the mold pin break alarm function can promptly detect failures such as broken locating pins, preventing mold damage and production interruptions. It is particularly suitable for high-cycle die casting island production lines.

Scuffing

Scuffing Hot spot

Hot spot Shrinkage porosity

Shrinkage porosityWe provide complete mold temperature control solutions to help you achieve stable quality, shorter cycles and reduced costs. Let’s find the right system for your needs.

Use high-precision sensors and fast controllers, optimize control algorithms (such as PID), and fine-tune system parameters.

Conduct regular inspections, replace worn parts promptly, and follow a maintenance plan covering cleaning, lubrication, and calibration.

Standard warranty is 12 months from acceptance. It covers non-human faults with free repairs, replacement of faulty parts, and technical support.

A response system is in place with performance tracking. If service is unsatisfactory, customers may escalate complaints to customer support, which ensures follow-up by assigned personnel.