| Type | MLJ Series Real-Time Monitoring | ||

| Model |

|

|

|

| Power supply | 380V50Hz | 380V50Hz | 380V50Hz |

| Cooling water circuits | Optional (one-to-one, one-to-many) | Optional (one-to-one, one-to-many) | Optional (one-to-one, one-to-many) |

| Pump power | 4kW | 5.5kW | 7.5kW |

| Cooling water discharge pressure | 0.4-0.8MPa | 0.4-0.8MPa | 0.4-0.8MPa |

| Water source (clean tap water/pure water) | 0.2-0.3MPa | 0.2-0.3MPa | 0.2-0.3MPa |

| Machine dimensions (L×W×H) | 1000×800×1450mm | 1000×800×1450mm | 1000×800×1450mm |

| Distributor dimensions (L×W×H) | 560×190×370mm | 560×190×370mm | 560×190×370mm |

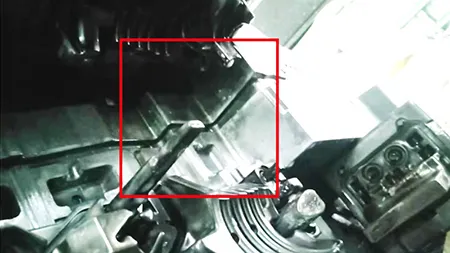

This die casting mold cooling machine is developed for die casting mold cooling to solve product defects caused by local overheating during the die casting production process. The Xinyu Mold Cooling Machine ensures effective cooling control of molds, keeping them at appropriate temperatures during production to guarantee product forming quality and production continuity.

Condensation

Condensation Mold sticking

Mold stickingWe provide complete mold temperature control solutions to help you achieve stable quality, shorter cycles and reduced costs. Let’s find the right system for your needs.

Use energy-efficient equipment, set reasonable temperature ranges, and reduce heating/cooling during non-production periods (e.g., standby mode).

Consider mold material, product process requirements, and production experience. For example, with aluminum alloy die casting, adjust parameters according to alloy grade and structure.

Standard warranty is 12 months from acceptance. It covers non-human faults with free repairs, replacement of faulty parts, and technical support.

A response system is in place with performance tracking. If service is unsatisfactory, customers may escalate complaints to customer support, which ensures follow-up by assigned personnel.